Advances made in the steelmaking process during the 1870’s saw the decline of the “iron age” and the rise of steel and tin plate. The use of tin plate had long been a very popular material for making household items such as stoves, lanterns, candlesticks, coffee pots, cooking pans, eating utensils, and children’s toys. It was becoming even more valuable with the increased manufacturing of tin cans for preserving food items. Tin plates or more accurately “tinned plates,” thin sheets of steel plating (“black sheets”) coated with tin, were extremely vital in the canning industry due to their ability to resist rust.

At the time the United States imported about 70% of its supply of tin plate from Wales, which was the undisputed center of the tin plate industry in the 1900’s. The McKinley Tariff of 1890, designed in part to jumpstart the infantile domestic tin plate industry, substantially raised the taxes on tin plate imports. It was under this and other “protectionism” laws that the United States underwent a rapid industrialization during the 1890’s, and became a leading exporter of various goods during the early 1900’s. Entrepreneurs in such places as Martins Ferry, Ohio, and Wheeling, West Virginia, were some of the first in the country to establish significant sheet plate or tin plate plants, or facilities that combined both operations. A cheaper material known as terne plate was also manufactured for use in the roofing and gutter industry.

One of the earliest mentions of the tin plate industry in New Castle, Pennsylvania, appeared in the New Castle News of Wednesday, August 19, 1891. It reported, “Early in the spring some gentlemen from Irondale, Ohio, were in New Castle with the purpose of building a tin plate mill, but their plans failed in some respects and they have since built a mill at Irondale that will be in operation soon. One of the gentlemen was a relative of Wm. Parshall of South Mill street.”

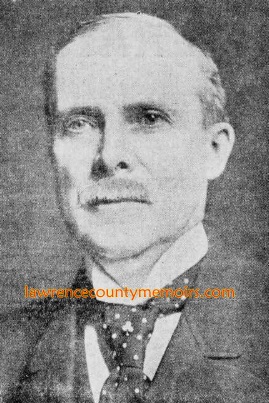

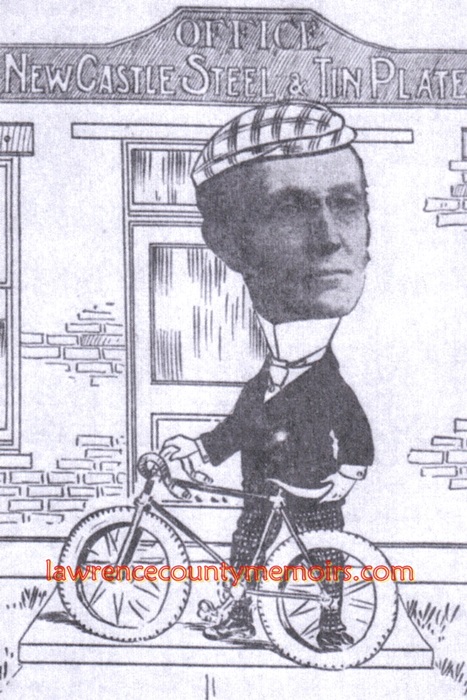

At the same time a local businessman named George M. Greer (1844-1926), a clean-living Methodist and talented musician, saw the McKinley Tariff as a major opportunity. Greer hailed from a highly regarded livestock farm in Neshannock Township. His father William Y. Greer ran the farm and was also involved in the banking industry. George Greer, along with his younger brother Charles (1848-1925), opened a music store in downtown New Castle and got involved in various other business ventures. He was a longtime parishioner and choir leader at the First Methodist Episcopal Church and a generous supporter of numerous charities. George Greer’s daring idea, in concert with his brother, was to fund and establish a tin plate factory in New Castle. He began looking at parcels of land in New Castle as early as 1889.

In July 1891 Greer became one of the original stockholders of a proposed steel plant to be constructed on the former site of the Crawford Iron & Steel Company along the eastern banks of the Shenango River. It all went according to plan this plant would supply the steel billet material required in the production of tin plate. The new plant, which opened in late 1892, was known as the Shenango Valley Steel Company and headed by President William E. Reis. While this plant was being constructed efforts to establish a tin plate plant were underway as well.

The New Castle News of Wednesday, January 6, 1892, ran a frontpage story about a new company being formed to manufacture tin plate in New Castle. It mentioned that George Greer “has devoted about three months to travel and the study of the tin plate business, with a view of ascertaining the business, structural and mechanical requirements of a successful mill, and he is assured that the industry can be profitably engaged in. Pending the coming of the charter, plans for building will be completed and a site chosen.

Greer gained the financial backing of some wealthy bankers and businessmen to include William Patterson, William Foltz, William E. Reis, and John Stevenson and soon secured some property along Moravia Street on the east bank of the Shenango River. Greer began overseeing the effort to erect a large manufacturing plant at the end of Furnace Street and work commenced in the summer of 1892. The New Castle News of Wednesday, August 17, 1892, reported, “One of the greatest tin plate mills in the country is being erected in this city…The railroad switch that is being put in will run along the side this building, making it very convenient for hauling materials and the finished product. The steel billets used in the manufacture of the tin plate will no doubt be procured from the Shenango Steel Works in this same as the same parties are interested in both plants.”

The New Castle News of Wednesday, March 8, 1893, reported on the progress with, “The new tin plate mill in this city is almost completed and George M. Greer stated to a News reporter recently that if nothing happened the works would be in successful operation May 1. The tin plate industry in the United States in growing very rapidly as seen by a recent report submitted by Special Agent (Ira) Ayer to the Treasury Department at Washington… There are now thirty-two firms manufacturing tin plate in the United States and the New Castle mill will rank well up with the largest in the country.” George Greer was elected as President and General Manager of the new company, while John Stevenson Jr. served as Vice President and William Foltz as Treasurer. His brother Charles was appointed as Secretary.

The tin plate industry, with few automated processes, required a high percentage of skilled workers not readily available in the United States. Greer brought in a host of skilled Welsh tin workers to manage the effort, and they in turn trained other workers to occupy such positions as rollers, doublers, heaters, openers, shearmen, tinners, picklers, and annealers. It was initially expected that his plant would employ about 300 people. The most highly skilled employees worked in the hot rolling mills, where steel bars were heated and rolled into thin sheets. The sheets were then moved to the tin house where they were bathed in acid, coated in molten tin, and cut into usable sizes. Another group known as assorters, usually women, would inspect, polish, and package the finish product for shipment. Most of the skilled men in the hot mills belonged to the Amalgamated Association of Iron, Steel, and Tin Plate Workers, known for its part in the disastrous Homestead Steel Strike of 1892.

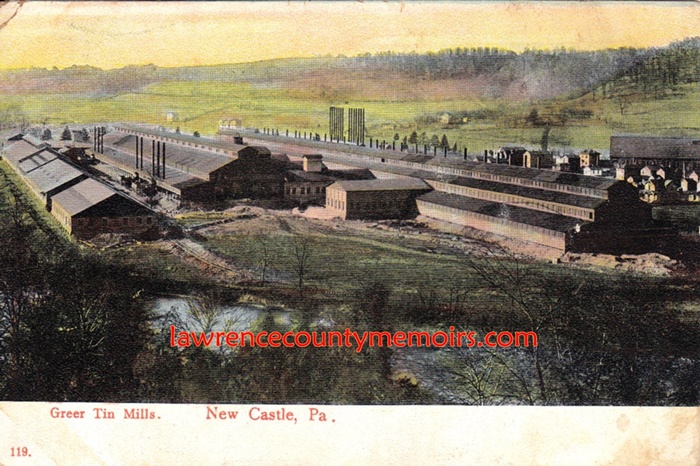

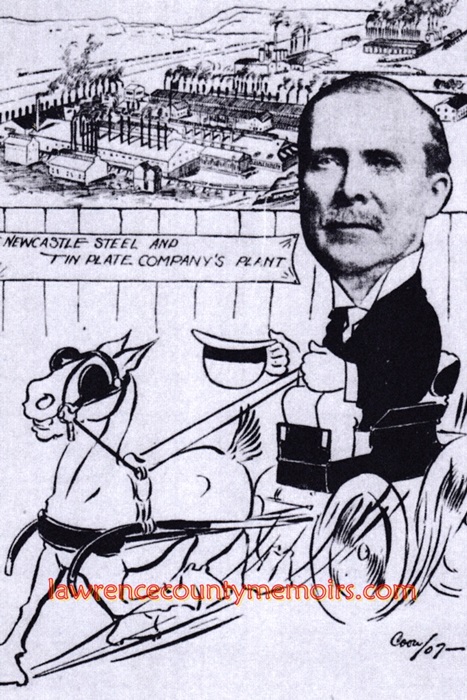

After careful planning Greer’s plant, with four separate “hot rolling mills” and known as the New Castle Steel and Tin Plate Company, went into preliminary operation in October 1893. Herbert C. Greer, the young son of Charles Greer, reportedly “dipped” the first sheet plate on Sunday, November 5, 1893. The company was an immediate financial success and was greatly expanded over the next few years.

Rival companies also sprung up by 1897. Limestone magnate George W. Johnson remodeled the existing Arethusa Iron Works (sheet metal plant) into the Neshannock Steel and Tin Plate Company (Johnson Works), while the powerful Shenango Valley Steel Company (Shenango Works) began construction of its own massive tin plate operation. The Shenango Sheet and Tin Plate Company was located on the west bank of the Shenango River along Mahoning Avenue.

European immigrants, including the Welsh, soon flooded into New Castle in search of employment in the tin mills, steel plants, iron works, limestone and coal mines, and with the railroads. The population exploded from 11,600 in 1890 to 28,000 in 1900. That’s a 141% increase within the decade. At the turn of the century New Castle was reported to be the fastest growing city in the country. By 1910 was population was over 38,000. New Castle was a center of industrial might and Greer led the way as its most prominent resident. The city prospered like never before or never since. The tin plate industry was the single most important factor in the growth of New Castle at that time.

The New Castle News of Wednesday, November 2, 1898, reported that William Williams, who owned the largest tin plate operation in Wales, sold his once-thriving business and was relocating to Pittsburgh to reinvest. The article mentioned the tin plate industry in New Castle with, “In this city will soon be turned out by long odds the most tin plate manufactured at any point in the Unites States. The buildings in which it is made are mammoth in proportions, covering acres of ground. There are the New Castle Steel & Tin company with 20 mills, the Shenango Valley Steel company’s plant with 30 mills and the lack plate works of the Neshannock Steel and Tinplate company with 6 mills – a grand total of 56 mills. Such a stupendous array of tin manufacturing establishments cannot be found in any other city the world over. To have forced the largest manufacture of tin in Wales to close up his plant and invest his millions in Western Pennsylvania, where the American rate of wages must be paid, is another of those protection victories that have been coming thick and fast in the past year.”

Before construction of the massive Shenango Sheet and Tin Plate Company was even completed all the tin plate outfits in the area were purchased and merged into the new American Tin Plate Company in December 1898. The company, established by Daniel G. Reid (the “Tin Plate King”), owned numerous sheet plate and tin plants around the country and practically controlled the industry now. Greer and other tin plate executives became very rich when they sold off their assets. George Greer remained onboard as district manager overseeing all the local plants. These included his old plant now known as the New Castle Works, the soon-to-be-completed Shenango Works, and the Sharon (or Farrell) Works to the north. The smaller Johnson Works in New Castle was soon closed down.

The New Castle News of Wednesday, March 1, 1899, reported, “George Greer, president of the New Castle Steel and Tin Plate company, until its absorption by the American Tin Plate company, has been appointed manager of all the mills in New Castle controlled by the combination. Mr. Greer now has charge of the New Castle and Neshannock mills, and will also have charge of the Shenango mill, when completed. Charles Greer, who was secretary of the New Castle company, is appointed assistant manager, and will divide with his brother the manifold duties of the conduct of the three large mills.”

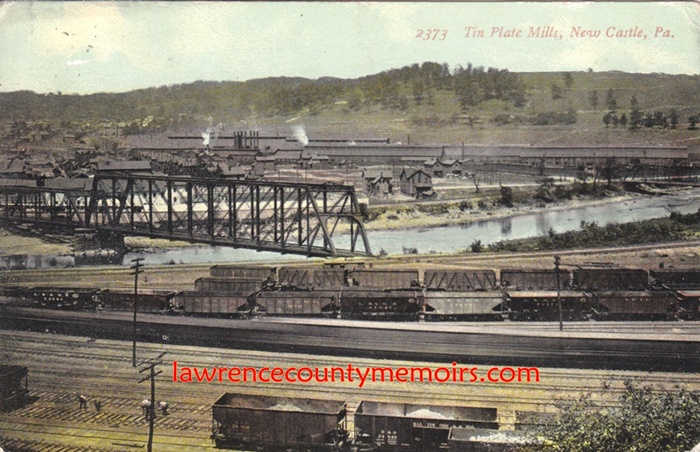

The Shenango Works, covering some forty-four acres, was finally opened in March 1899 with about 2,500 employees. The New Castle News of Sunday, March 13, 1901, printed an excerpt from the Pittsburg Labor World the read, “The Shenango works contain 30 hot mills, 30 tandem cold roll mills, 44 tinning machines, equipped with the latest improved branning and cleaning machines. The mills in the New Castle district are modern and are equipped with the best improved machinery and appliances for handling the raw material, as well as the finished product, in a systematic and economical way.”

The Shenango Works, eventually expanded to 40 hot mills, and was the largest tin plate manufacturing plate in the country. With the New Castle Works and Shenango Works in full operation New Castle was the largest single producing site of tin plate in the entire world. They kept the railroads busy with a constant flow of freight.

European immigrants, including the Welsh, soon flooded into New Castle in search of employment in the tin mills, steel plants, iron works, limestone and coal mines, and with the railroads. The population exploded from 11,600 in 1890 to 28,000 in 1900. That’s a 141% increase within the decade. At the turn of the century New Castle was reported to be the fastest growing city in the country. By 1910 was population was over 38,000. New Castle was a center of industrial might and Greer led the way as its most prominent resident. The city prospered like never before or never since. The tin plate industry was the single most important factor in the growth of New Castle at that time.

The New Castle News of Wednesday, November 2, 1898, reported that William Williams, who owned the largest tin plate operation in Wales, sold his once-thriving business and was relocating to Pittsburgh to reinvest. The article mentioned the tin plate industry in New Castle with, “In this city will soon be turned out by long odds the most tin plate manufactured at any point in the Unites States. The buildings in which it is made are mammoth in proportions, covering acres of ground. There are the New Castle Steel & Tin company with 20 mills, the Shenango Valley Steel company’s plant with 30 mills and the lack plate works of the Neshannock Steel and Tinplate company with 6 mills – a grand total of 56 mills. Such a stupendous array of tin manufacturing establishments cannot be found in any other city the world over. To have forced the largest manufacture of tin in Wales to close up his plant and invest his millions in Western Pennsylvania, where the American rate of wages must be paid, is another of those protection victories that have been coming thick and fast in the past year.”

Before construction of the massive Shenango Sheet and Tin Plate Company was even completed all the tin plate outfits in the area were purchased and merged into the new American Tin Plate Company in December 1898. The company, established by Daniel G. Reid (the “Tin Plate King”), owned numerous sheet plate and tin plants around the country and practically controlled the industry now. Greer and other tin plate executives became very rich when they sold off their assets. George Greer remained onboard as district manager overseeing all the local plants. These included his old plant now known as the New Castle Works, the soon-to-be-completed Shenango Works, and the Sharon (or Farrell) Works to the north. The smaller Johnson Works in New Castle was soon closed down.

The New Castle News of Wednesday, March 1, 1899, reported, “George Greer, president of the New Castle Steel and Tin Plate company, until its absorption by the American Tin Plate company, has been appointed manager of all the mills in New Castle controlled by the combination. Mr. Greer now has charge of the New Castle and Neshannock mills, and will also have charge of the Shenango mill, when completed. Charles Greer, who was secretary of the New Castle company, is appointed assistant manager, and will divide with his brother the manifold duties of the conduct of the three large mills.”

The Shenango Works, covering some forty-four acres, was finally opened in March 1899 with about 2,500 employees. The New Castle News of Sunday, March 13, 1901, printed an excerpt from the Pittsburg Labor World the read, “The Shenango works contain 30 hot mills, 30 tandem cold roll mills, 44 tinning machines, equipped with the latest improved branning and cleaning machines. The mills in the New Castle district are modern and are equipped with the best improved machinery and appliances for handling the raw material, as well as the finished product, in a systematic and economical way.”

The Shenango Works, eventually expanded to 40 hot mills, and was the largest tin plate manufacturing plate in the country. With the New Castle Works and Shenango Works in full operation New Castle was the largest single producing site of tin plate in the entire world. They kept the railroads busy with a constant flow of freight.

In March 1901 financier John Pierpont Morgan Sr. organized an effort to merge Carnegie Steel, Federal Steel, and National Steel to form the U.S. Steel Corporation. U.S. Steel went on to be the most world’s largest steel producer and the most powerful corporation in the entire world. The merger also involved the plants of the Daniel Reid’s American Tin Plate Company, including those in New Castle.

Almost immediately the leaders of the Amalgamated Association of Iron, Steel, and Tin Plate Workers began clashing with the newly created U.S. Steel, which wanted the unions broken, for simple recognition of its ability to operate in the plants. A strike was called and commenced on August 10, 1901, and lasted about five weeks. In all over 150,000 employees were on strike or forced out of work as a result, including over 3,500 tin mill workers in New Castle. The tin mills in New Castle were briefly idled before the workers returned to work with no real gains made. The strike was a complete failure for the union and it lost much of its influence.

U.S. Steel reorganized its tin plate assets under the moniker of the American Sheet and Tin Plate Company in January 1904. Greer remained in charge of all local plants, including the mill in Sharon, as district manager. When Greer finally retired from the industry effective July 1, 1908, his lone district manager post was dissolved and split among three new general manager positions. Bert “B.J.” Ross became general manager at the New Castle Works, David S. Pyle (Greer’s former second in command) took over at the Shenango Works, and William H. Davis assumed control of the Sharon Works.

Another large strike commenced on July 1, 1909, when the Amalgamated Association orchestrated another walkout against U.S. Steel. A reported 3,000 tin mill workers in New Castle were out of work. This time, and strike was long and bitter and lasted well over a year. It was certainly made worse locally by the fact that George Greer was no longer involved with management. Strikebreakers were called in from Cleveland and violence erupted on the streets of New Castle. The tin mills were put back in operation with the strikebreakers, but the quality of the output suffered. The strike was called off in August 1910 and was a devastating defeat for the union. Many skilled tin mill workers left the area and never returned, while others applied for their old jobs back. The plants were soon put back in regular operation, but the union, although it remained in existence, never recovered and faced backlash from many former members.

George Greer retired from the industry to concentrate on his other substantial business interests. He was involved with several banks, steel mills, and cement plants. He built an impressive home in the North Hill District in 1905, erected the new six-story Greer Block on North Mercer Street in 1907, and continued to raise prized cattle on his old homestead. He was very active with the First Methodist Church and was involved in a handful of fraternal and charitable organizations in the city. Greer remained a lifelong resident of New Castle, and died after an operation in a hospital in Baltimore, Maryland, in April 1926. His wife Alice (White) Greer died at their North Hill residence just a few hours later. His brother Charles, who basically retired from business after 1909, had preceded him in death in February 1925. George and Charles Greer, two of New Castle’s most prominent citizens, were both laid to rest in Oak Park Cemetery.

When Greer stepped down the American tin plate industry was already on the decline. The American Sheet and Tin Plate Company, which had enjoyed a monopoly, consolidated its sheet plate and tin plants, closing many smaller facilities and enlarging the bigger ones. With fewer plants and automated techniques more and more workers were put out of work. Smaller independent companies began to make some headway as the government fought to control the power of the monopolies. Utensils and other household items made of tin were no longer in vogue, and other materials like aluminum would slowly come to prominence in the canning industry. The price of tin plate fell sharply by 1910 and the industry was no longer as lucrative as it once was.

The New Castle Works and Shenango Works continued in operation for many years. They eventually came under the Carnegie-Illinois Steel Corporation, a subsidiary of U.S. Steel. Much of the finished product these two plants turned out went directly to the nearby American Can Company in Mahoningtown. That local canning plant primarily made tin cans for condensed milk companies. Other pallets of tin plate sheets were shipped by rail to the Pacific Northwest to make cans for processed salmon, and also to Hawaii for canned pineapples.

The two plants were periodically shutdown, sometimes for months on end, due to a lack of demand. The tough times of the 1930’s took a toll on many businesses in the area including the tin plate mills. The New Castle Works, shut down for a time from 1931-1933, was finally closed for good in 1937. In late May 1941 the city council and county commissioners, with Walter W. Duff acting as trustee, closed a deal to acquire the property, consisting of twenty acres and most of the buildings, with the Carnegie-Illinois Steel Company. It was thought that it would be necessary for the plant to be converted for defense use.

The New Castle Works was turned over to the Standard Steel Spring Company of Coraopolis, Pennsylvania in early 1942. It was renovated and became a defense plant making vital materials for the U.S. military effort during World War II. It continued in service after the war making heavy duty springs for automobiles, buses, and military vehicles. The company was involved in several mergers over the years to become the Rockwell Spring and Axle Company in 1953, Rockwell Standard in 1958, North American Rockwell in 1967, and Rockwell International in 1973.

The plant on Furnace Street reached its peak of about 500 employees in 1979, but a lack of demand forced cutbacks over the next few years. In early 1982 it was announced that the plant, known as the Suspension Components Division, would be closed within a few months. After forty years of service the plant was shuttered on Friday, May 28, 1982, and the remaining 160 employees were out of work. This was another economic blow to the community as it followed, or was about to followed by, the closing of Johnson Bronze (January 1981), the Pentax Foundry (June 1981), and Mesta Machine (June 1982). A portion of the old plant buildings are still in use today, at least for a time as a rail car repair facility operated by the Kasgro Rail Corporation.

The larger Shenango Works survived a while longer, but it too was shuttered in early 1940. The Shenango Works was put back in operation in 1942 as a defense plant, making aluminum for the U.S. military. It was operated by the Pittsburgh-based Aluminum Company of America (ALCOA), which controlled operations at five vital aluminum plants across the country. The Valley Manufacturing Company, a sheet mill operation, also began leasing a portion of the plant. The federal government put the plant up for sale in early 1947, but ALCOA was forbidden to purchase the plant due to stringent anti-monopoly laws. The plant was sold in December 1948 to the Bossert Company, which became part of the Rockwell Spring and Axle Company in 1953. From that point on, the two former tin plate plants in New Castle were under the control of the same company (Rockwell). The plant was converted to produce axels for heavy duty trucks. In October 1991 the parent company, Rockwell International, announced it was closing the axle plant, known as the Highway Axle Division, and moving operations elsewhere. The 536 employees would be phased out within the next few years.

In April 1993 the plant was sold to the McDuff Corporation of Pittsburgh, but Rockwell leased some space as it continued to wind down operations with 75 employees. Rockwell ceased production on Thursday, May 27, 1993, and began closing up shop for good. The massive plant was soon converted into a multi-tenant industrial site known as the McDuff Industrial Park. Several tenants have since come and gone but BPI Inc., a company that processes mineral by-products and markets the finished material, still occupies the majority of the former plant.

The heyday of the tin plate industry in the United States (roughly 1895-1907) was short lived, but its importance to the growth of New Castle can’t be stressed enough. As the 1890’s came to a close New Castle, with a thriving industrial sector led by the tin plate plants, was one of the fastest growing cities in the entire country. It was this phenomenal growth that gave rise to the now forgotten nickname of “Little Pittsburgh.”

The Shenango Works (shown above) near Mahoningtown was at one time the largest tin plate operation in the world. The combined tin plate mills in New Castle were often referred to as the “Greer Mills.” (c1908) Full Size |

The massive Shenango Works was opened for operation in January 1899. This plant was finally closed in 1940 and soon converted into a war industry plant producing vital aluminum. (c1903) Full Size |

This popular old postcard shows tin mill workers in Pittsburgh hard at work. (1907) Full Size |

Another view of the massive Shenango Works (c1915) Full Size |

Tin mill workers from the Shenango Works. (c1914) Full Size |

The marching band of the American Sheet & Tin Plate Company. (c1910) Full Size |

Comments

David Parsons #

My grandfather William Parsons worked at the Tin Mill probably from 1910-1950. He came from Wales in 1888. All of his brothers either worked in the tin mills, Aliquippa steel mills, or coal mines.

Suzanne Munson #

George and Charles Greer were my great-great uncle and great grandfather, respectively. Thank you for including their story in your website.

Amy Stahl #

George Greer was my great-great grandfather. Such an interesting story! I never knew he was also a musician. I always thought my music genes came from my father’s family, but now I know they came from my mother’s as well!

Ruth Morrison #

Thank you for posting this information and pictures of the American Sheet and Tin Plate Company.

My Grandfather, Joseph Oczkowski was working at ASTPC in 1918 as listed on his WW1 Registration card. I know that he worked more years than just this one and would like to find out more information.

If anyone knows if there are employment records or the names of the people in the pictures listed, I would appreciate if you would contact me at rumorct@att.com.

Our family has a story that at first he went to work under the name, Joseph Martin because it was easier to say or write the name. My Uncle claimed to have had check stubs with this name but they were burned in a house fire.

So interesting that the company had a marching band. This may have explained why Joseph played an instrument. None of the relatives knew why, only that he played somewhere away from the house.

David McCORMICK #

My Dad, his Father and brothers all worked in the hotmill section of the Shenango Works. Once a farm boy from Grant City in Lawrence County, my grandfather, Hugh A. McCormick initially worked in the construction of the Clairton Works of Carnegie Steel. In 1907, Hugh returned to New Castle and became a heater helper, and later a heater in the hotmill. He retired from US Steel in 1927. Beginning in 1913, in seriatim, his sons Raymond, Ellsworth (“Hinee”), Harry, James and in finally in April 1936 my Father, Arthur P. McCormick worked in the hotmill. Ray, Ellsworth, Harry and Jim were all hotmill rollers. My Dad began and a srewboy, and quickly advanced to be a catcher’s helper, and catcher, rougher and was learning to “roll fours” when the 1938 shutdown occurred. Dad (along with many others) was offered a transfer to the Irvin Works or some offered jobs at Gary, Indiana. My Dad accepted work at the Irvin Works in 1938. There (after Navy service in WWII), Dad was qualified as a roller in 1948. My Dad’s brothers remained in the New Castle -Sharon area after the final shutdown of the Shenango Works (as a hotmill) in 1940. In addition to Mr. Greer who contributed so much to the steel industry in New Castle, one remembers Mr. David S. Pyle (1875-1956) who began working at the Shenango Works in 1892 and advanced under US Steel to be plant superintendent by his retirement in June 1936. Another name from the past would be Mr. George Zeurner who was the hotmill superintendent. Thank you to all who contributed pictures.

Ken Hansen #

I came to this web site after removing a sheet of tin roofing from my adobe house built in 1912. It had a label American Sheet and Tin Plate Co. Pittsburgh PA. Is there a warranty? it only lasted 105 years! And YES, NEW Mexico, a state in the USofA it is between AZ and TX.

Skip Heller #

Samuel Johns, who immigrated from Llanelli, Wales, moved to New Castle in 1900 and worked in the tin mills there until 1915. He was a doubler. He was my 2nd Great Uncle and came to the US to be near his 3 brothers.

We are looking for more information on him and his wife and daughter. Any help would be appreciated.

JOHN E ROBERTS #

MY GREAT-UNCLE JOHN QUINCY LEVI ROBERTS WORKED AT THIS PLACE. JOHN Q.L. ROBERTS FROM OHIO.

LIKE TO KNOW IF IS IN THE PIX. ABOVE

JOHN E ROBERTS #

MY GREAT-UNCLE JOHN QUINCY LEVI ROBERTS WORKED AT THIS PLACE. JOHN Q.L. ROBERTS FROM OHIO.

LIKE TO KNOW IF IS IN THE PIX. ABOVE

Rachel Tipton #

My great great grandfather worked there in 1900, Robert Liggett Stewart. Lived on PA Ave in census. Would love to know if there are records too. Would love to know more about him.

Rachel Tipton

Comment